Technical Data

Application Fields

Mingzhi's stepper motors are widely used in various types of equipment to provide the necessary motion control. This includes:

• Office Automation: Printers, scanners, copiers, multifunction printers, etc.

• Stage Lighting: Light direction control, focusing, color change and spot control, lighting effects, etc.

• Banking: ATMs, bill printing, bank card production, counting machines, etc.

• Medical Field: CT scanners, blood analyzers, biochemical analyzers, etc.

• Industry: Textile machinery, packaging machinery, robots, conveyors, assembly lines, labeling machines, etc.

• Communication: Signal modulation, mobile antenna positioning, etc.

• Security: Motion control of surveillance cameras.

• Automotive: Oil valve/gas valve control, car light steering systems, etc.

• What is a Stepper Motor?

A stepper motor is an electromechanical device that directly converts electrical pulses into mechanical motion. By controlling the sequence, frequency, and number of electrical pulses applied to the motor coils,

it can achieve control over the direction, speed, and rotation angle of the stepper motor. Without relying on a closed-loop feedback control system with position sensing,

a simple, low-cost open-loop control system can be formed using a stepper motor and its matching driver, allowing for

precise position and speed control.

• Characteristics of Mingzhi Stepper Motors

• Precise Position Control

The angle to which the shaft turns is determined by the number of input pulses. The position error is very small (less than 1/10 degree), and the error does not accumulate.

• Accurate Speed

The speed of the stepper motor depends on the frequency of the input pulses. Because the speed is precise and easy to adjust, stepper motors are widely used

in various motion control fields.

• Forward/Reverse Rotation, Emergency Stop, and Locking Functions

Effective control of motor torque and position can be achieved across the entire speed range, including static torque. In the locked state of the motor (

current exists in the motor windings, but there is no external rotating pulse command input), a certain torque output is still maintained.

• Precise Position Control at Low Speeds

The stepper motor can run smoothly at very low speeds without the need for a gearbox, while outputting a large torque, avoiding

power loss and angular position deviation, while also reducing costs and saving space.

• Longer Lifespan

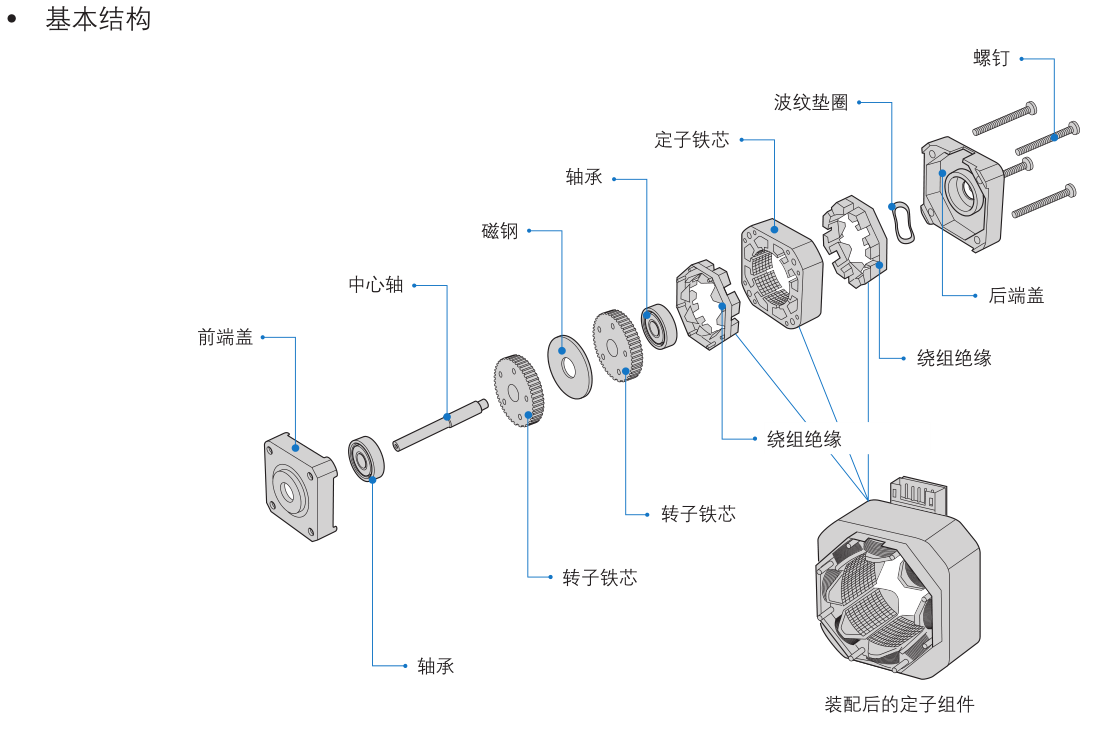

The brushless design of the stepper motor ensures a long lifespan. The lifespan of a stepper motor usually depends on the bearings.

Working Principle

Working Principle

The stepper motor driver controls the windings of the stepper motor to energize in a certain sequence based on external control pulses and direction signals through its internal logic circuit, causing the motor to rotate forward or backward, or to lock.

Taking a 1.8-degree two-phase stepper motor as an example: when both phase windings are energized, the motor output shaft will remain stationary and locked in position. The maximum torque to keep the motor locked at rated current is the holding torque. If the current in one phase winding changes direction, the motor will rotate one step (1.8 degrees) in a predetermined direction. Similarly, if the current in the other phase winding changes direction, the motor will rotate one step (1.8 degrees) in the opposite direction. When the current through the coil windings is sequentially reversed to energize, the motor will achieve continuous step rotation in the predetermined direction, with very high operational accuracy. For a 1.8-degree two-phase stepper motor, it takes 200 steps to complete one rotation.

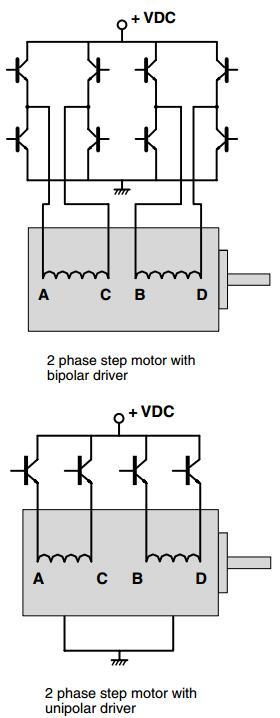

Two-phase stepper motors have two winding forms: bipolar and unipolar. Bipolar motors have only one winding coil per phase, and the current must sequentially reverse within the same coil to energize during continuous rotation, requiring eight electronic switches for sequential switching in the driver circuit design.

Unipolar motors have two coils with opposite polarities per phase, and during continuous rotation, only alternating energization of the two coils on the same phase is needed. The driver circuit design requires only four electronic switches.

In bipolar drive mode, because each phase's winding coil is 100% energized, the output torque of the motor in bipolar drive mode is about 40% higher than in unipolar drive mode.